Our Vision is Your Future.

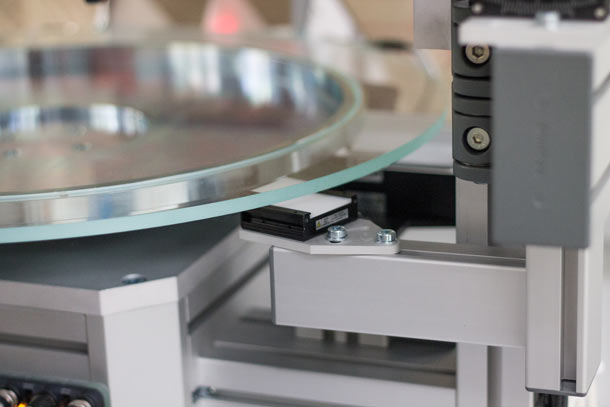

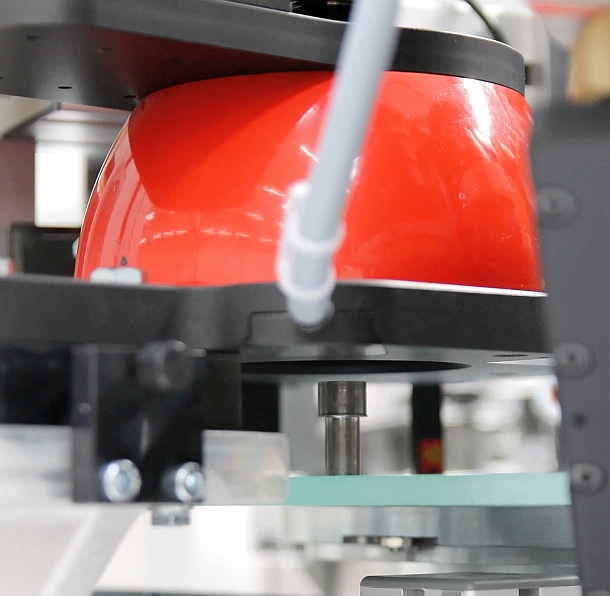

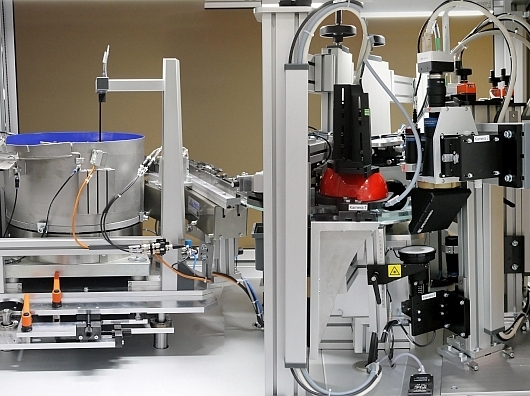

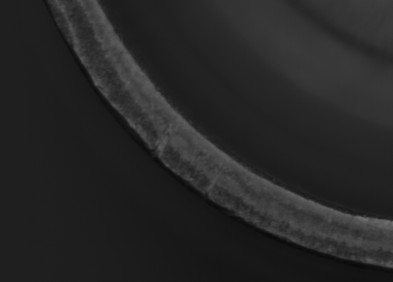

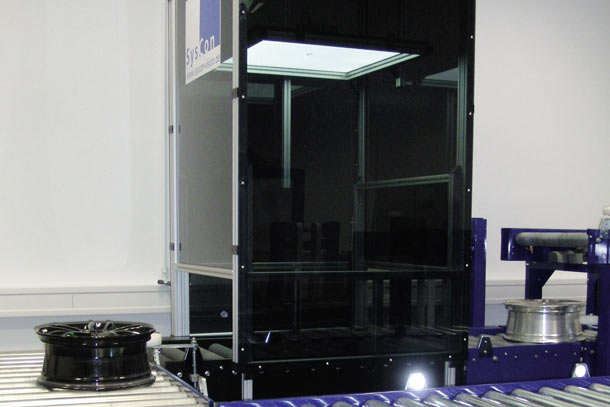

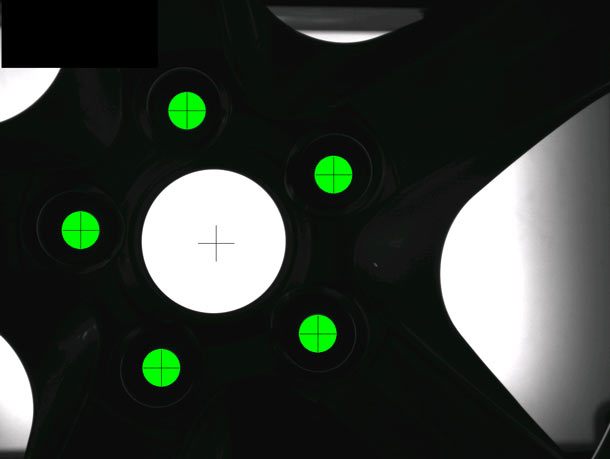

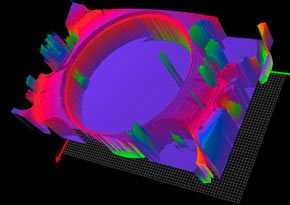

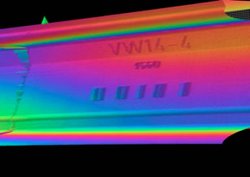

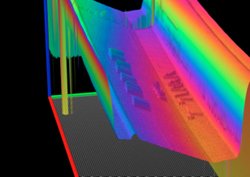

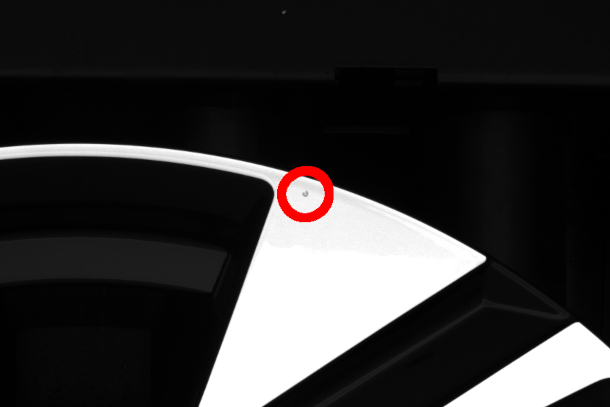

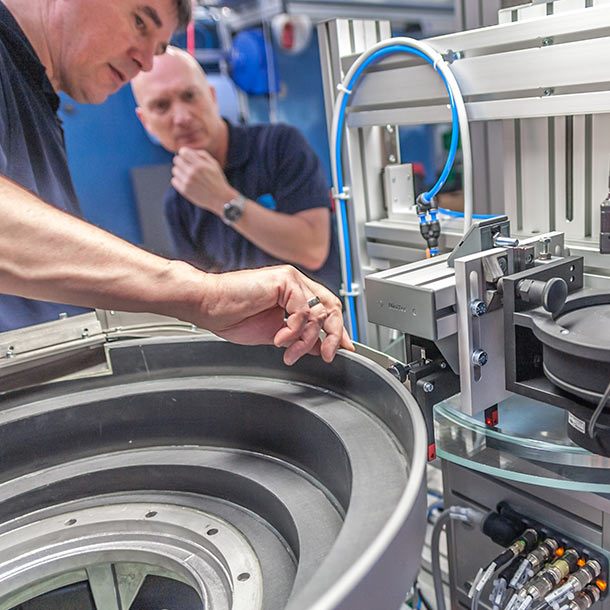

As a system company and service provider, SysCon GmbH specializes in the concept design and performance of control tasks in the areas of automation and quality assurance using industrial image processing and laser measurement technology.

Already since 1995, we have been delivering image processing solutions to all industrial branches, mainly the automotive industry and its suppliers, the consumer goods industry and jewelry producers as well as the food and beverage industry.

SysCon operates all over the world. Customers in Europe, Asia and America rely on our expertise in image processing.